Dynamic sensing robot-dog Spot astounded the public in a 2015 viral video with its mannerisms and agility, qualities allowing the quadruped to jump, fetch and, maybe most shockingly, twerk.

Starting as a research project, Spot has now developed into a commercially available product advertised on Boston Dynamics’ website as useful for “factory floors, construction sites, research labs and beyond.”

Although Boston Dynamics promises Spot will provide “day in and day out” service, the dog cannot keep up with the 8-hour shifts of typical factory workers, as its battery only lasts 1.5 hours. And Spot is no anomaly: most autonomous robots have similar runtimes, and flying robots like quadcopters last only around 30 minutes.

“There's a disconnect between the operation time of these robots and the time that you actually want to use them,” James Pikul, an associate professor of mechanical engineering at UW-Madison, told The Daily Cardinal. “We have our world that we live in, which operates in these four — or eight — hour increments, and robots are pretty far from operating that long.”

In an interview, Pikul outlined his vision for bio-inspired robots with advanced battery technologies that can, in a sense, “eat” metal and “bleed.” He said his approach to storing energy could create robots operating with the same energy density and runtime as a greyhound dog in under 10 years.

What makes animal endurance so much better?

One of the reasons humans and other animals can survive for so long without nutrients is the high energy density of fat. The corresponding measure determining robot endurance is battery energy density. Increasing the amount of energy that can be stored in a battery of constant size would also increase robot runtime.

Based on Pikul’s calculations, creating an autonomous robot with energy density similar to a greyhound would require a battery with energy density of 1,000 to 2,000 watt-hours per kilogram. Currently, lithium-ion batteries are around 250 watt-hours per kilogram, meaning battery capacity would have to improve by four to eight times the current standard.

Battery energy density currently improves by about 7% per year.

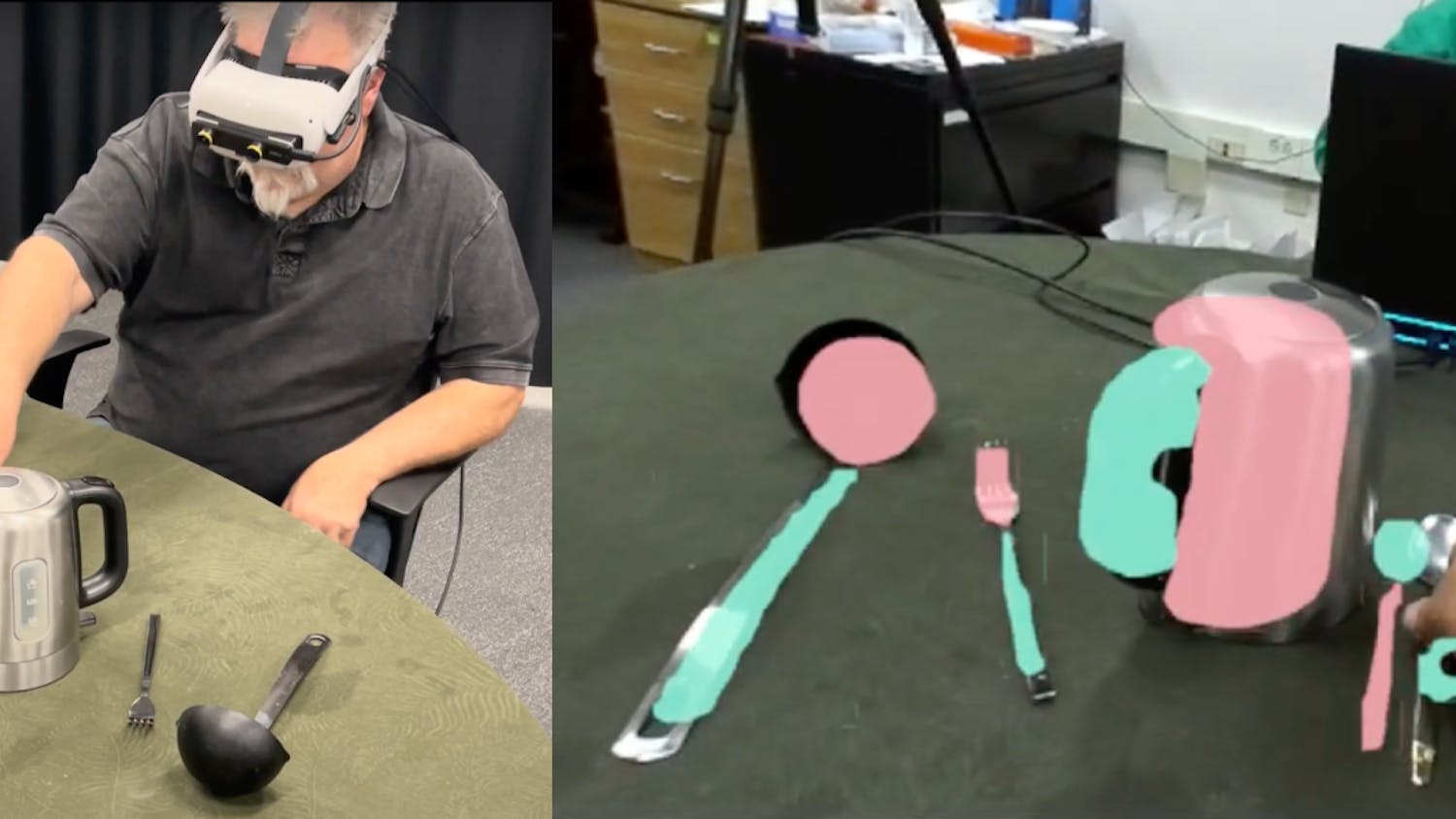

Pikul’s background is in the subfield of soft robotics, which focuses on robots made of bendable materials like hydrogels, often emulating human skin or muscle, as opposed to the traditional hard robots with metallic outerwear. The field of soft robotics is especially influenced by biology, which inspired Pikul’s ideas for robots processing metal similar to animals processing food.

“It's natural for us to think about what biology does well, and how we can implement that into our robotic systems, but people haven't really done it for energy before,” Pikul said. “We can go for a week without eating… and that's very, very different from the hour and a half of battery life for a robot.”

Metal diets and silver blood

A robot could eat solid metal “wafers” and discard metal oxides resembling dirt in a manner similar to the animal digestive and excretory systems, Pikul said, adding there are “chemical” differences to robot implementation of these systems but not “fundamental big changes.”

Though the specific mechanism for digestion is an “open spot” in research, Pikul envisioned that robots could pick up a credit-card sized piece of metal, its “snack,” insert it into a slot, and process it through a synthetic digestive system that oxidizes the metal, retains the energy, and discards the de-energized metal.

Like animal remains are composted and their materials recycled through the ecosystem, Pikul suggested the metal passing through robots could be processed in facilities for reuse, mimicking natural cycles.

“Nitrogen cycles, water cycles, carbon cycles — these cycles are how we take energy from the sun and reuse it in a way that allows all life to prosper,” Pikul said.

He suggested energy from solar panels could produce metal chips from dirt or sand, which contains metal oxides. The chips could be consumed by robots and recycled back into metal oxides. Then, the solar panels could again re-energize those metal oxides into usable material, creating an infinite source of reusable energy.

Pikul’s paper proposed that robot designs utilize a single-electrolyte system similar to blood to transport energy throughout the robot. Currently, automotives like John Deere tractors and Caterpillar construction equipment drive mechanical movements with hydraulic fluids, essentially highly pressurized, hot fluids used to more efficiently transmit force.

In another of Pikul’s papers, he showed replacing a robot’s hydraulic fluids with liquid batteries — in other words, “robot blood” — led to a threefold increase in energy density over a robot with traditional lithium ion batteries.

“You gain energy for free, basically, because you need to put the fluid in the robot anyway,” Pikul said. “Now that fluid actually does something extra, stores energy.”

Besides transporting nutrients, like proteins or antibodies, to cells around the body, blood also reduces burn damage by absorbing heat from an affected area on the skin. Heat is also the most significant constraint on the scaling of processing chips. Actuators, which allow robots to move similar to human joints, are also hindered by overheating issues, according to Pikul. Robot blood, in the form of liquid batteries, could dissipate heat similar to human blood.

Future research

Batteries are composed of three main components: a negatively charged anode, a positively charged cathode and an electrolyte, which moves ions between the anode and the cathode, maintaining their charges. When the battery is in use, electrons passing from anode to cathode generate energy used, for example, to power a car.

The way batteries currently function make solar-powered extragenic cycles impossible, Pikul said. Current batteries’ reactions could be corrupted if exposed to natural elements, like water and air, because the elements might contaminate the materials within the battery.

Metal-air batteries, with a lithium or aluminum anode and open-air cathode, could solve this problem, Pikul said. Human energy processing operates in a similar manner to these batteries, where fat stores energy akin to the metal anode, and the cathode, oxygen, is breathed in. But more research into metal-air viability is necessary.

While Pikul’s recent paper explored the effects of new battery topologies on robotic systems, the lab primarily conducts research into new batteries for electrified aircrafts or shipboards that could reduce carbon emissions.

“What we showed in the paper is the energy density of batteries that you need to get [a robotic system] equivalent to a greyhound or a human,” Pikul said. “That's what you need to electrify aviation for passenger aircraft as well. If you can solve the problem for robots, that solves it for a lot of other things.”

Approaching the problem of energy density from a biological perspective gives Pikul’s lab a leg up compared to researchers “trying to take an electric vehicle battery and upgrade it,” he said.

Future research would work on developing fluids that have high energy density, which would require “different types of chemistry and a different way of designing the battery.”

Pikul said the “marriage of robots and energy storage” has wide-ranging applications for many types of electrified systems.

“It’s a big, big boon to society, and it changes the way that you design systems,” Pikul said. “And that's our goal.”